What is NPSH and what is its application in pumps

The explanation of NPSH is very simple.

NPSH or net positive suction head is one of the main parameters that should be considered when choosing a pump. But what do we mean when we talk about NPSH? And why is it so important?

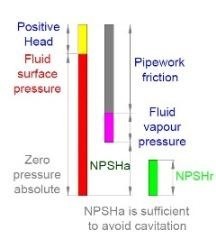

First of all, we need to distinguish between two different NPSH values: existing NPSH and required NPSH.

Available NPSH:

Available NPSH, commonly abbreviated as NPSHa, is the value calculated by the plant engineer. and can be roughly defined as the result of the absolute pressure of the fluid at the pump inlet minus the vapor pressure of the liquid. It is usually expressed in meters.

Required NPSH

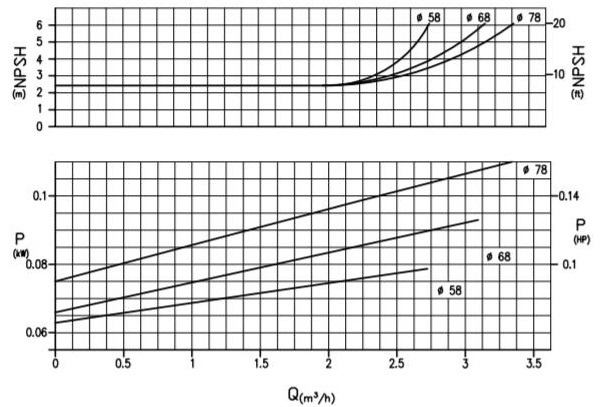

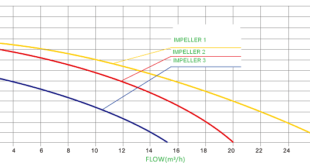

The required NPSH (NPSHr) is a value given by the pump manufacturer that describes the energy losses within the pump that typically occur when liquid enters through the pump impeller. The amount expressed as the head of the fluid (usually in meters). This is a pump requirement and depends on various factors such as: design, impeller dimensions and pump speed, flow rate speed, etc.

NPSH: Why is it so important?

As we said, NPSH is a basic item in pump selection and sizing. In fact, NPSHa must be higher than NPSHr for the pump to work properly. If not, cavitation can occur, reducing pump performance and in many cases seriously damaging the pump.

Cavitation is a physical phenomenon that can occur in a pump. When the system pressure falls below the vapor pressure of the fluid, it causes small gas bubbles to form inside the liquid. These bubbles collapse immediately when liquid is poured into the impeller, beyond the impeller inlet, due to increased pressure.

This decay produces fine particles with a very high impact on the propeller, which are significantly damaging. Because the impeller is unbalanced, vibration and all of its related issues can occur, including seal failure and serious bearing damage.

NPSHA > NPSHR

For this reason, the plant engineer has to keep NPSH values in mind at all times. The pump performance curve usually contains an NPSHr plot so that the engineer can check the operating conditions. In fact, it is necessary that the NPSHr of the pump is lower than the NPSHa at the plant. The minimum margin of safety between NPSHr and NPSHa should be at least 0.5 m.

Only if this ratio is observed, the pump will work properly and cavitation will be avoided.

Ontrose industrial corporation Inc. Engineering and supply of industrial projects

Ontrose industrial corporation Inc. Engineering and supply of industrial projects