Guide to Pump Types, Fluids, and Applications in the Oil and Gas Industry

Introduction: Pumps serve as the heart of fluid transportation systems in the oil and gas industry. Understanding the diverse range of pump types, the fluids they handle, their advantages, and proper selection is crucial for optimizing efficiency and reliability in various applications. This comprehensive guide explores the key aspects of pumps in the oil and gas sector.

Pump Types:

1. Centrifugal Pumps:

- Related Fluids: Suitable for low-viscosity fluids, including water, crude oil, and light hydrocarbons.

- Advantages: Efficient, cost-effective, and suitable for a wide range of applications.

- Selection Guide: Ideal for continuous-flow processes like water injection and circulation systems.

2. Positive Displacement Pumps:

- Related Fluids: Handles both low and high-viscosity fluids, making them versatile for oil and gas applications.

- Advantages: Precise control, suitable for high-pressure applications.

- Selection Guide: Appropriate for tasks requiring a fixed volume of fluid per pump revolution, such as metering and injection.

3. Diaphragm Pumps:

- Related Fluids: Suitable for handling corrosive and viscous fluids, including chemicals and slurries.

- Advantages: Leak-proof operation, self-priming capabilities.

- Selection Guide: Ideal for metering, dosing, and applications demanding high reliability.

4. Submersible Pumps:

- Related Fluids: Used for pumping liquids from wells, sumps, and reservoirs, including water and crude oil.

- Advantages: Efficient in submerged conditions, ideal for offshore drilling.

- Selection Guide: Appropriate for applications requiring fluid extraction from submerged locations.

5. Screw Pumps:

- Related Fluids: Suitable for handling high-viscosity fluids, heavy crude oil, and drilling mud.

- Advantages: Gentle fluid handling, minimal shear forces.

- Selection Guide: Effective for pumping viscous substances in oil and gas processes.

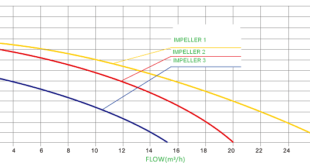

Impeller Types:

1. Closed Impellers:

- Advantages: High efficiency due to reduced fluid recirculation.

- Applications: Clean and low-viscosity fluid handling.

2. Open Impellers:

- Advantages: Suitable for fluids with solids, reduces clogging.

- Applications: Handling slurries, wastewater, and fluids with particulates.

3. Semi-Open Impellers:

- Advantages: Balance between efficiency and solids handling.

- Applications: Wastewater treatment, slurry pumping.

4. Vortex Impellers:

- Advantages: Efficient handling of liquids with high solids content.

- Applications: Sewage pumping, handling debris-laden fluids.

Utility Pump Types:

1. Utility Pumps:

- Applications: General-purpose tasks such as water transfer, dewatering, and fluid circulation.

- Selection Guide: Versatile and suitable for a variety of non-specialized applications.

Process Pump Types:

1. Multistage Pumps:

- Applications: High-pressure fluid transportation in offshore platforms, refineries, and petrochemical plants.

- Selection Guide: Suitable for applications requiring elevated pressures.

2. Reciprocating Plunger Pumps:

- Applications: Hydraulic fracturing (fracking), high-pressure fluid injection.

- Selection Guide: Ideal for high-pressure operations demanding controlled fluid flow.

Body Types:

1. Casing Types:

- Axial Split Case: Ease of maintenance with access to the impeller.

- Radial Split Case: Suited for high-pressure applications with a horizontally split casing.

- Vertical Split Case: Space-efficient design with a vertically split casing.

2. Pump Housing Types:

- Monobloc or Close-Coupled: Compact design with integrated pump and motor.

- Frame-Mounted: Separate pump and motor connected by a coupling for flexibility.

3. Material Construction:

- Cast Iron: General-purpose applications.

- Stainless Steel: Corrosive environments and high durability requirements.

- Duplex Stainless Steel: Enhanced corrosion resistance and strength.

Conclusion: Selecting the right pump type, impeller design, and body construction is essential for optimizing fluid handling in the oil and gas industry. This comprehensive guide provides insights into the diverse range of pumps and their applications, aiding in informed decision-making for efficient and reliable operation

Ontrose industrial corporation Inc. Engineering and supply of industrial projects

Ontrose industrial corporation Inc. Engineering and supply of industrial projects