Comprehensive Guide to Temperature Transmitters: Types, Specifications, Principles, Outputs, and Advantages

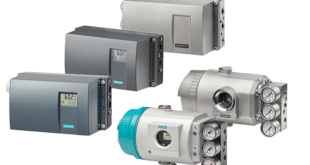

In the realm of industrial process control, temperature is a critical parameter that demands precise measurement and control. Temperature transmitters play a pivotal role in converting temperature readings into electrical signals for efficient monitoring and regulation. In this comprehensive guide, we will delve into the world of temperature transmitters, exploring their types, specifications, working principles, output signals, advantages, and applications across industries.

I. Introduction to Temperature Transmitters

A. What is a Temperature Transmitter?

A temperature transmitter is an essential component in industrial instrumentation designed to measure temperature accurately and convert the measured temperature into an electrical signal. This signal is then transmitted to control systems for monitoring, control, and data analysis.

B. Importance of Temperature Transmitters

Temperature transmitters are crucial in maintaining optimal operating conditions in various industries. They provide accurate and reliable temperature data, enabling precise control and contributing to process efficiency, safety, and product quality.

II. Types of Temperature Transmitters

Temperature transmitters come in various types, each tailored to specific applications. Understanding these types is essential for selecting the most suitable transmitter for a given scenario.

A. Analog Temperature Transmitters

Analog temperature transmitters provide a continuous output signal, often in the form of a current loop (e.g., 4-20 mA) or voltage (e.g., 0-5 V, 0-10 V). They are widely used in industrial processes requiring real-time temperature monitoring.

B. Digital Temperature Transmitters

Digital temperature transmitters use digital communication protocols such as HART, Profibus, or Foundation Fieldbus. These transmitters offer advanced features, including remote configuration, diagnostics, and enhanced communication capabilities.

C. Wireless Temperature Transmitters

Wireless temperature transmitters eliminate the need for physical wiring, offering flexibility in installation and reducing installation costs. They communicate wirelessly with control systems, making them suitable for remote or hard-to-reach locations.

III. Specifications of Temperature Transmitters

Understanding the specifications of temperature transmitters is crucial for selecting the right device for a specific application. Key specifications include:

A. Temperature Range

The temperature range indicates the minimum and maximum temperatures a transmitter can accurately measure. Choosing the right temperature range is essential for optimal performance.

B. Accuracy

Accuracy is a measure of how closely the transmitter’s output corresponds to the actual temperature. It is typically expressed as a percentage of the full-scale output.

C. Output Signal

Temperature transmitters can have various output signals, including analog signals (e.g., 4-20 mA, 0-5 V) or digital signals (e.g., HART, Profibus). The choice depends on the requirements of the control system.

D. Response Time

Response time indicates how quickly the transmitter can react to changes in temperature. Faster response times are crucial in applications with rapid temperature variations.

E. Environmental Conditions

Temperature transmitters must operate within specific environmental conditions, including temperature, humidity, and vibration. Ensuring compatibility with the application environment is vital for reliable performance. The related sensors can be protected by using of thermowells.

IV. Working Principle of Temperature Transmitters

Understanding the working principle of temperature transmitters is fundamental to grasp how these devices convert temperature into electrical signals.

A. Resistance Temperature Detectors (RTDs)

RTDs use the change in electrical resistance of a metal, typically platinum, with temperature. The resistance change is proportional to the temperature, and this relationship is utilized to measure and transmit temperature.

B. Thermocouples

Thermocouples consist of two different metals joined at one end. When the junction is exposed to temperature variations, it generates a voltage proportional to the temperature difference. This voltage is then converted into a temperature reading.

C. Thermistors

Thermistors are temperature-sensitive resistors that exhibit a significant change in resistance with temperature. The resistance-temperature relationship is nonlinear, and the resistance is measured to determine the temperature.

V. Output Signals of Temperature Transmitters

Temperature transmitters generate electrical signals that convey temperature information to control systems. The most common output signals include:

A. 4-20 mA Signal

The 4-20 mA signal is a standardized current loop widely used in industrial applications. The current value within this range corresponds to the measured temperature, with 4 mA typically representing the lowest temperature and 20 mA representing the highest.

B. Voltage Signals (0-5 V, 0-10 V)

Voltage signals are another common output option. The voltage varies proportionally to the temperature, with 0 V typically representing the lowest temperature and 5 V or 10 V representing the highest, depending on the transmitter’s specifications.

C. Digital Outputs (HART, Profibus, Foundation Fieldbus)

Modern temperature transmitters often come with digital communication protocols such as HART, Profibus, or Foundation Fieldbus. These protocols allow for enhanced communication, diagnostics, and configuration capabilities.

VI. Advantages of Temperature Transmitters

Understanding the advantages of temperature transmitters highlights their significance in industrial processes:

A. Precision and Accuracy

Temperature transmitters provide precise and accurate temperature measurements, allowing for tight control over industrial processes and ensuring product quality.

B. Remote Monitoring and Control

With advancements in technology, temperature transmitters can be integrated into remote monitoring systems, allowing for centralized control, monitoring, and configuration.

C. Real-time Data

Temperature transmitters provide real-time temperature data, enabling quick identification of deviations from desired operating conditions and prompt corrective actions.

D. Cost Efficiency

By preventing temperature-related issues or inefficiencies, temperature transmitters contribute to the longevity of equipment, reducing maintenance costs and preventing costly downtime.

VII. Applications of Temperature Transmitters

Temperature transmitters find applications across diverse industries, contributing to process efficiency, safety, and control. Some notable applications include:

A. Chemical and Petrochemical Industry

In chemical and petrochemical processes, temperature transmitters are used to monitor and control temperature in reactors, distillation columns, and storage tanks.

B. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, temperature transmitters play a crucial role in maintaining optimal indoor climate conditions and energy efficiency.

C. Food and Beverage Industry

Temperature transmitters are essential in food and beverage processing to ensure precise temperature control during various stages, such as cooking, cooling, and fermentation.

D. Pharmaceuticals and Biotechnology

In pharmaceutical manufacturing, temperature transmitters are vital for maintaining precise temperature conditions in processes like fermentation and reaction vessels.

E. Energy Generation

Temperature transmitters are used in power plants to monitor and control temperatures in boilers, turbines, and other critical components.

VIII. Future Trends in Temperature Transmitter Technology

As technology continues to advance, temperature transmitter technology is expected to evolve with several trends:

A. Integration with IoT and Industry 4.0

Temperature transmitters are likely to become more interconnected with the Internet of Things (IoT) and Industry 4.0, enabling enhanced data analytics, predictive maintenance, and seamless integration into smart manufacturing systems.

B. Miniaturization and Enhanced Portability

Advancements in miniaturization may lead to smaller, more portable temperature transmitters that maintain or even improve their performance characteristics.

C. Increased Sensing Technologies

The development of new sensing technologies may further enhance the accuracy, reliability, and versatility of temperature transmitters, expanding their applicability across various industries.

D. Enhanced Communication Protocols

The integration of advanced communication protocols may become more prevalent, enabling even more robust and versatile communication between temperature transmitters and control systems.

IX. Conclusion

Temperature transmitters stand as indispensable tools in the ever-evolving landscape of industrial automation. Their ability to accurately measure temperature, convert it into electrical signals, and communicate with control systems is foundational to the efficiency, safety, and reliability of industrial processes.

Understanding the types, specifications, working principles, output signals, applications, and benefits of temperature transmitters is crucial for making informed decisions in selecting and implementing these devices in diverse industrial settings. As technology continues to progress, temperature transmitters will undoubtedly play a pivotal role in shaping the future of industrial automation and control systems.

Ontrose industrial corporation Inc. Engineering and supply of industrial projects

Ontrose industrial corporation Inc. Engineering and supply of industrial projects