Comprehensive Guide to Level Transmitters: Types, Specifications, Principles, Outputs, and Advantages

Level transmitters play a crucial role in industrial processes by providing accurate and real-time measurement of fluid levels. These devices are essential for maintaining optimal operating conditions, ensuring safety, and enhancing efficiency across various industries. In this comprehensive guide, we will explore the world of level transmitters, covering their types, specifications, working principles, output signals, advantages, and applications.

I. Introduction to Level Transmitters

A. What is a Level Transmitter?

A level transmitter is an instrument designed to measure the level of a substance, usually a liquid, in a tank or container. It converts the level measurement into an electrical signal for monitoring, control, and data analysis in industrial processes.

B. Importance of Level Transmitters

Level transmitters are vital in industries where precise monitoring and control of fluid levels are crucial. They provide valuable data for managing inventory, preventing spills, ensuring safety, and optimizing processes in sectors such as chemical, petrochemical, water treatment, and more.

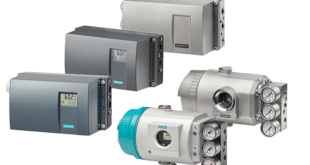

II. Types of Level Transmitters

Level transmitters come in various types, each tailored to specific applications and working principles. Understanding these types is essential for selecting the most suitable transmitter for a given scenario.

A. Capacitance Level Transmitters

Capacitance level transmitters utilize the capacitance change between the sensor and the fluid to determine the level. They are suitable for a wide range of applications and are often used in liquids with low dielectric constants.

B. Ultrasonic Level Transmitters

Ultrasonic level transmitters use ultrasonic waves to measure the distance between the sensor and the liquid surface. They are non-contact and ideal for applications where the fluid is corrosive or where contact measurement is impractical.

C. Radar Level Transmitters

Radar level transmitters operate by emitting microwave signals that bounce off the liquid surface and return to the sensor. These transmitters are effective in applications with varying temperatures, pressures, or complex tank geometries.

D. Hydrostatic Level Transmitters

Hydrostatic level transmitters measure the pressure exerted by the fluid column above the sensor. They are suitable for applications with constant fluid density and are commonly used in open tanks or vessels.

E. Differential Pressure Level Transmitters

Differential pressure level transmitters measure the pressure difference between the liquid level and a reference pressure at the bottom of the tank. They are versatile and applicable to various fluid types.

III. Specifications of Level Transmitters

Understanding the specifications of level transmitters is crucial for selecting the right device for a specific application. Key specifications include:

A. Measurement Range

The measurement range indicates the minimum and maximum levels that a transmitter can effectively measure. It is essential to choose a transmitter with a range that covers the intended operating conditions.

B. Accuracy

Accuracy is a critical specification, indicating how closely the transmitter’s output corresponds to the actual fluid level. It is typically expressed as a percentage of the full-scale output.

C. Resolution

Resolution represents the smallest change in level that a transmitter can detect. Higher resolution allows for more precise monitoring, especially in applications where small level changes are significant.

D. Response Time

Response time indicates how quickly the transmitter can react to changes in fluid level. Faster response times are crucial in applications with rapid level variations.

E. Material Compatibility

The materials used in the construction of the transmitter must be compatible with the fluid being measured to ensure longevity and accuracy.

IV. Working Principle of Level Transmitters

Understanding the working principle of level transmitters is fundamental to grasp how these devices convert fluid level measurements into electrical signals.

A. Capacitance Principle

Capacitance level transmitters operate based on the principle that the capacitance between the sensor and the fluid changes with the level. This change is then converted into an electrical signal for measurement.

B. Ultrasonic Principle

Ultrasonic level transmitters use the time taken for ultrasonic waves to travel to the liquid surface and back to calculate the fluid level. The speed of sound in the air provides a reliable measurement.

C. Radar Principle

Radar level transmitters emit microwave signals that reflect off the liquid surface. The time taken for the signal to return is used to calculate the fluid level accurately.

D. Hydrostatic Principle

Hydrostatic level transmitters measure the pressure exerted by the fluid column above the sensor. The hydrostatic pressure is directly proportional to the fluid level.

E. Differential Pressure Principle

Differential pressure level transmitters measure the pressure difference between the liquid level and a reference point. This difference is converted into an electrical signal proportional to the fluid level.

V. Output Signals of Level Transmitters

Level transmitters generate electrical signals that convey fluid level information to control systems. The most common output signals include:

A. 4-20 mA Signal

The 4-20 mA signal is a standardized current loop widely used in industrial applications. The current value within this range corresponds to the fluid level, with 4 mA typically representing the lowest level and 20 mA representing the highest.

B. Voltage Signals (0-5 V, 0-10 V)

Voltage signals are another common output option. The voltage varies proportionally to the fluid level, with 0 V typically representing the lowest level and 5 V or 10 V representing the highest, depending on the transmitter’s specifications.

C. Digital Outputs (HART, Profibus, Foundation Fieldbus)

Modern level transmitters often come with digital communication protocols such as HART, Profibus, or Foundation Fieldbus. These protocols allow for enhanced communication, diagnostics, and configuration capabilities.

VI. Advantages of Level Transmitters

Understanding the advantages of level transmitters highlights their significance in industrial processes:

A. Accuracy and Precision

Level transmitters provide accurate and precise measurements, enabling tight control over fluid levels in various applications.

B. Non-Contact Measurement

Non-contact level measurement, as seen in ultrasonic and radar transmitters, reduces the risk of sensor contamination and eliminates the need for direct contact with corrosive or hazardous fluids.

C. Versatility

Level transmitters come in various types, each suitable for specific applications and environments, making them versatile for diverse industrial needs.

D. Remote Monitoring and Control

With the integration of advanced communication protocols, level transmitters allow for remote monitoring, control, and configuration, contributing to operational efficiency.

VII. Applications of Level Transmitters

Level transmitters find applications across diverse industries, contributing to process efficiency, safety, and control. Some notable applications include:

A. Chemical and Petrochemical Industry

In the chemical and petrochemical sector, level transmitters are used to monitor and control fluid levels in storage tanks, reactors, and processing vessels.

B. Water and Wastewater Treatment

In water treatment plants, level transmitters play a crucial role in monitoring water levels in tanks, reservoirs, and various treatment processes.

C. Oil and Gas Industry

Level transmitters are utilized in the oil and gas industry for monitoring fluid levels in storage tanks, ensuring efficient logistics and preventing overflows.

D. Food and Beverage Processing

In the food and beverage industry, level transmitters are employed to control fluid levels in tanks during various processing stages, contributing to product quality and safety.

E. Pharmaceuticals and Biotechnology

Level transmitters play a vital role in pharmaceutical and biotech manufacturing by ensuring precise control of fluid levels in reactors and storage vessels.

VIII. Future Trends in Level Transmitter Technology

As technology continues to advance, level transmitter technology is expected to evolve with several trends:

A. Integration with IoT and Industry 4.0

Level transmitters are likely to become more integrated with the Internet of Things (IoT) and Industry 4.0, enabling enhanced data analytics, predictive maintenance, and seamless integration into smart manufacturing systems.

B. Miniaturization and Enhanced Portability

Advancements in miniaturization may lead to smaller, more portable level transmitters with improved power efficiency and ease of installation.

C. Advanced Sensor Technologies

The development of advanced sensor technologies may enhance the accuracy, reliability, and versatility of level transmitters, expanding their applicability across various industries.

D. Environmental Monitoring Capabilities

Future level transmitters may incorporate additional environmental monitoring capabilities, providing information on factors such as temperature, pressure, and humidity for a comprehensive understanding of the operating conditions.

IX. Conclusion

Level transmitters stand as indispensable tools in the landscape of industrial automation and process control. Their ability to accurately measure fluid levels, convert measurements into electrical signals, and communicate with control systems is foundational to the efficiency, safety, and reliability of industrial processes.

Understanding the types, specifications, working principles, output signals, advantages, and applications of level transmitters is crucial for making informed decisions in selecting and implementing these devices in diverse industrial settings. As technology continues to progress, level transmitters will undoubtedly play a pivotal role in shaping the future of industrial automation and control systems.

Ontrose industrial corporation Inc. Engineering and supply of industrial projects

Ontrose industrial corporation Inc. Engineering and supply of industrial projects